Here is some plans I have had setting on the shelf and I finally got around to cleaning them up well enough to throw out here on the blog. Hope you like them.

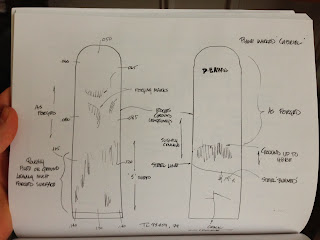

This is a complex profile moulding plane featuring a 7/8" ogee profile just like I showed off in a prior post. It is a side escapement plane and is a very functional size. A 5/8" size is quite useful as well for general work. This should give you an idea of how to produce the other sizes if you follow the same principals of layout.

I highly recommend forming the profile of the sole before doing any of the other layout and cutting. It makes sure that the mouth is located at exactly the right spot. If you do it at the end then you may remove too much material getting the profile shape just right and then have a very wide mouth.

By the way I always cut the profile on a complex profile plane first whether it is a moulding plane or bench plane such as the raised panel bench plane. This is the opposite advice I recently saw in the article for the raised panel plane from Popular Woodworking. Try it both ways and you will see it results in a much better plane cutting the profile first.

CLICK HERE TO GO TO THE DOWNLOAD PAGE. (Click on the download button in the upper right corner of the new page to begin download.) These are offered as a free download intended for non commercial / personal use only. These are copyright protected.

If I made any errors anywhere in the plans please let me know so I can update them.

Enjoy!

Wednesday, November 27, 2013

Thursday, November 21, 2013

Tapered Bench Plane Blades for Traditional Wooden Planes

UPDATE:

Am I the last person to know about this? Lee Valley sells tapered plane blades! Check them out here. Ok so they are shorter than my bench plane blades. That is my only complaint. I really don't know where my head has been stuck. Does anyone know how long these have been for sale? I am currently slapping my forehead and doing back flips all at the same time. All I can do is laugh. Thanks to everyone who has emailed to inform me about these. :)

Original post:

So I have been working on getting some tapered wooden bench plane blades made. You may or may not be familiar with what I am talking about. If you have used a side escapement moulding plane then you are familiar with the tapered blades they have. Well this is no different really.

All the planes I have made up to this point are single iron planes, that is the plane blades have no cap iron, and I have made them with just a flat iron, without any taper. I know that you can make a very good plane with a flat iron but there are some things that are far better with a tapered iron.

Here is just a couple of reasons. One is that the blade is wedged more securely thus vertically eliminating the blade shifting while in use either side to side or backwards. This more secure fit really reduces and chatter that could result from less than ideal fit from normal seasonal wood movement.

The biggest advantage I believe is that when the back of the blade is maintained flat during sharpening a taper toward the heel of the blade keeps the blade form actually becoming a taper toward the cutting edge on a flat blade since it is being reduced in thickness on that end. This would of course result in a blade that shifts backwards in use and becoming loose. Along with that issues is that a flat blade seems to change position more when setting the wedge while a tapered one doesn’t. This seems contrary to what you might imagine. I could go on but I think you are probably seeing the value of a tapered blade so far.

While researching how to machine these blades and just before I was about to go on a buying spree for more tools (metal working stuff; milling machine, surface grinder, etc.) I met a retired machinist in his eighties that convinced me to let him produce them for me. I think I am glad that I agreed if not for the very fact I know they will be right the first time and that I can get the blades I want in a reasonable amount of time and on to making the planes I want to make. After all I am a woodworker first, the metal work is something I would like to learn but I need to stay focused as much as I can. After all the original blades for these antique 18th century planes would have been blacksmith made.

Speaking of that, I am basing the blades on the single iron plane blades that are shown in "The Tool Chest of Benjamin Seaton" 2nd Edition. They are from a british plane found in a tool chest from 1797. Thank you to blacksmith Peter Ross for getting me to the proper historically accurate blade design.

I want to thank Raney Nelson of Daedtoolworks for getting me on the right track for getting these machined in the correct fashion. That is to say the right machines and the right tooling.

Here are a few photos of the process and the results so far in our test material. I hope to have the actual blades cut, shaped and in my hands next week! Then they will be off for heat treating.

Am I the last person to know about this? Lee Valley sells tapered plane blades! Check them out here. Ok so they are shorter than my bench plane blades. That is my only complaint. I really don't know where my head has been stuck. Does anyone know how long these have been for sale? I am currently slapping my forehead and doing back flips all at the same time. All I can do is laugh. Thanks to everyone who has emailed to inform me about these. :)

Original post:

So I have been working on getting some tapered wooden bench plane blades made. You may or may not be familiar with what I am talking about. If you have used a side escapement moulding plane then you are familiar with the tapered blades they have. Well this is no different really.

All the planes I have made up to this point are single iron planes, that is the plane blades have no cap iron, and I have made them with just a flat iron, without any taper. I know that you can make a very good plane with a flat iron but there are some things that are far better with a tapered iron.

Here is just a couple of reasons. One is that the blade is wedged more securely thus vertically eliminating the blade shifting while in use either side to side or backwards. This more secure fit really reduces and chatter that could result from less than ideal fit from normal seasonal wood movement.

The biggest advantage I believe is that when the back of the blade is maintained flat during sharpening a taper toward the heel of the blade keeps the blade form actually becoming a taper toward the cutting edge on a flat blade since it is being reduced in thickness on that end. This would of course result in a blade that shifts backwards in use and becoming loose. Along with that issues is that a flat blade seems to change position more when setting the wedge while a tapered one doesn’t. This seems contrary to what you might imagine. I could go on but I think you are probably seeing the value of a tapered blade so far.

While researching how to machine these blades and just before I was about to go on a buying spree for more tools (metal working stuff; milling machine, surface grinder, etc.) I met a retired machinist in his eighties that convinced me to let him produce them for me. I think I am glad that I agreed if not for the very fact I know they will be right the first time and that I can get the blades I want in a reasonable amount of time and on to making the planes I want to make. After all I am a woodworker first, the metal work is something I would like to learn but I need to stay focused as much as I can. After all the original blades for these antique 18th century planes would have been blacksmith made.

Speaking of that, I am basing the blades on the single iron plane blades that are shown in "The Tool Chest of Benjamin Seaton" 2nd Edition. They are from a british plane found in a tool chest from 1797. Thank you to blacksmith Peter Ross for getting me to the proper historically accurate blade design.

I want to thank Raney Nelson of Daedtoolworks for getting me on the right track for getting these machined in the correct fashion. That is to say the right machines and the right tooling.

Here are a few photos of the process and the results so far in our test material. I hope to have the actual blades cut, shaped and in my hands next week! Then they will be off for heat treating.

Stay tuned!

Sunday, November 17, 2013

How to Make the Mouth, Abutment & Wedge For A Wooden Bench Plane

The hardest part of a wooden bench plane to wrap your head around is with out a doubt also the soul and heart of the very plane itself. It is where all the good stuff happens. It is the parts you can't see but that matters the most.

No online picture of an antique bench plane would ever give you the details that you need to make the critical functioning parts. You would be too timid to probably dissemble one if you were to even happen upon the exact one you wanted to duplicate while at flee market or vintage tool shop.

Well no need to now. Even though this post won't go into step by step how to form all the critical parts at least you will see what they are supposed to look like which is half the battle, or more.

While in the process of making a demo plane for a post to show the inter workings (and I had actually already cut it in half in order to show off the inter workings) Doug Moulder came along and drew up my jack plane plans in a 3D model. Great work Doug! So there is a nice plane cut in two parts if anyone wants one. I may or may not get around to photo graphing it to show how the inter workings come together. Funny thing is that after all that I realized that I could have just cut the parts into the side of a block of wood without doing it the hard way and then cutting it in half. Sometimes I wonder...

Anyhow here is the good stuff you have been waiting for. Enjoy!

Also I have a real interesting project in the works. Tapered plane blades. More on that to come!

Well no need to now. Even though this post won't go into step by step how to form all the critical parts at least you will see what they are supposed to look like which is half the battle, or more.

While in the process of making a demo plane for a post to show the inter workings (and I had actually already cut it in half in order to show off the inter workings) Doug Moulder came along and drew up my jack plane plans in a 3D model. Great work Doug! So there is a nice plane cut in two parts if anyone wants one. I may or may not get around to photo graphing it to show how the inter workings come together. Funny thing is that after all that I realized that I could have just cut the parts into the side of a block of wood without doing it the hard way and then cutting it in half. Sometimes I wonder...

Anyhow here is the good stuff you have been waiting for. Enjoy!

Also I have a real interesting project in the works. Tapered plane blades. More on that to come!

Friday, November 15, 2013

Dark Side Of The Moon

I have been deep into completing some plans that have been in the works for about 8 months now. I have been dragging these out and am finally on the home stretch.

I know that many people have been asking Curtis Buchanan if he is going to put out the plans for his continuous arm chair and the answer is yes as soon as Caleb finishes them! So you can blame me on your having to wait so long. The fact that I have been slow to blog as of late is that I am trying desperately to get these finished in time for Curtis' You tube videos on making this chair are posted up.

We are making these extra special this time with a front and side view and we will see if we decide to fit the top view in as well. The plans will be large and detailed with all the turning patterns and bending forms just like before, only better. These plans will really inspire you to make this chair and give you all the details that are so critical for this type of chair.

Here is a sneak peek.

I know that many people have been asking Curtis Buchanan if he is going to put out the plans for his continuous arm chair and the answer is yes as soon as Caleb finishes them! So you can blame me on your having to wait so long. The fact that I have been slow to blog as of late is that I am trying desperately to get these finished in time for Curtis' You tube videos on making this chair are posted up.

We are making these extra special this time with a front and side view and we will see if we decide to fit the top view in as well. The plans will be large and detailed with all the turning patterns and bending forms just like before, only better. These plans will really inspire you to make this chair and give you all the details that are so critical for this type of chair.

Here is a sneak peek.

Subscribe to:

Posts (Atom)